CNC Machining Services:

We supply widely CNC machining services as below:

Screw, Nut, and Hardware Manufacturing:

Production Equipment:

♦Lathes machine / CNC Lathes machine

.jpg)

Processing capacity:

♦3-AxisCNC Automatic Lathe machine

(1).jpg)

Processing capacity:

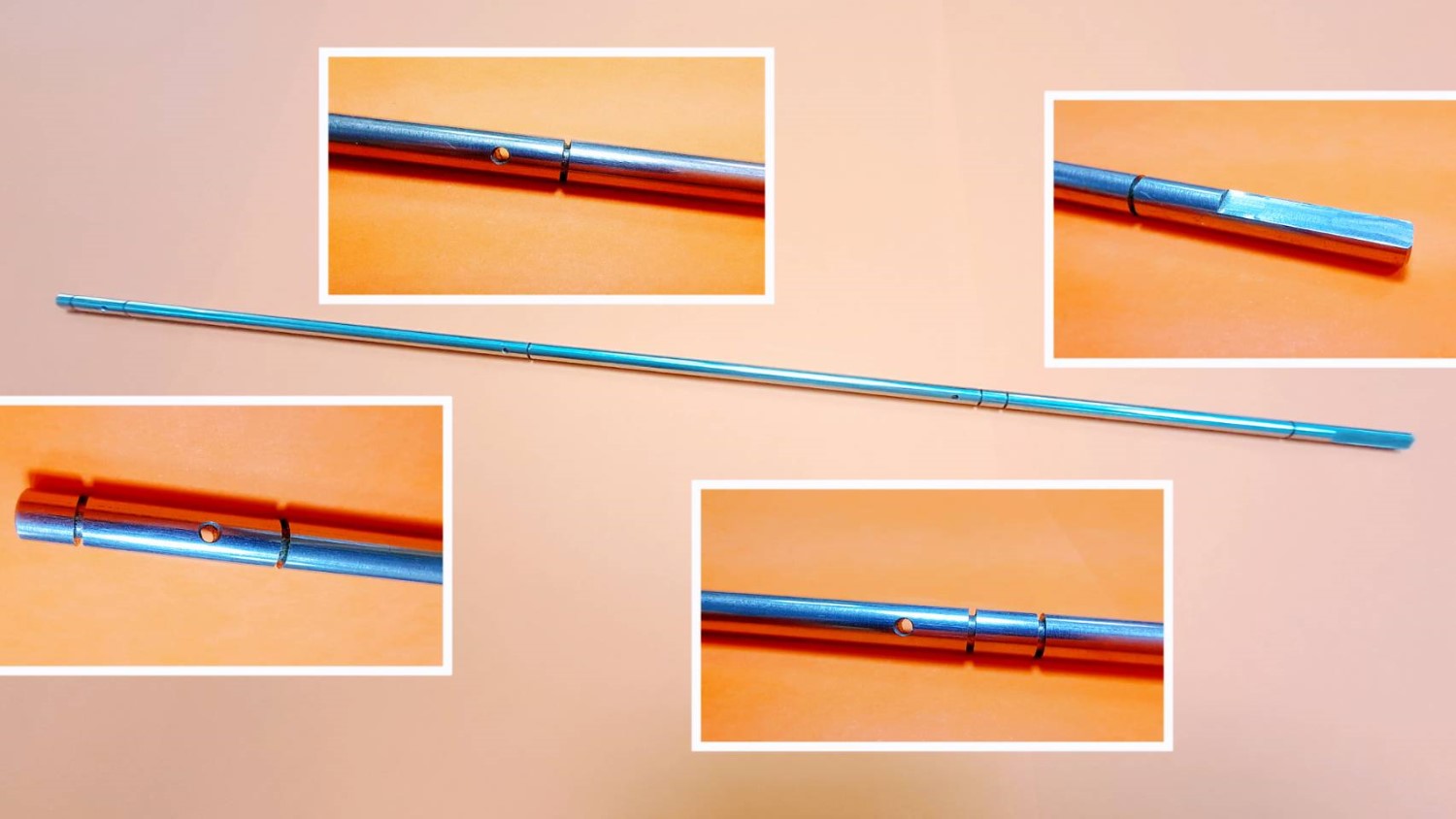

Printer toner roller shaft: Out diameter: φ4.68mm L:48CM

♦Milling machine / CNC Milling machine

.jpg)

.jpg)

Processing capacity:

Materials:

Surface Treatment:

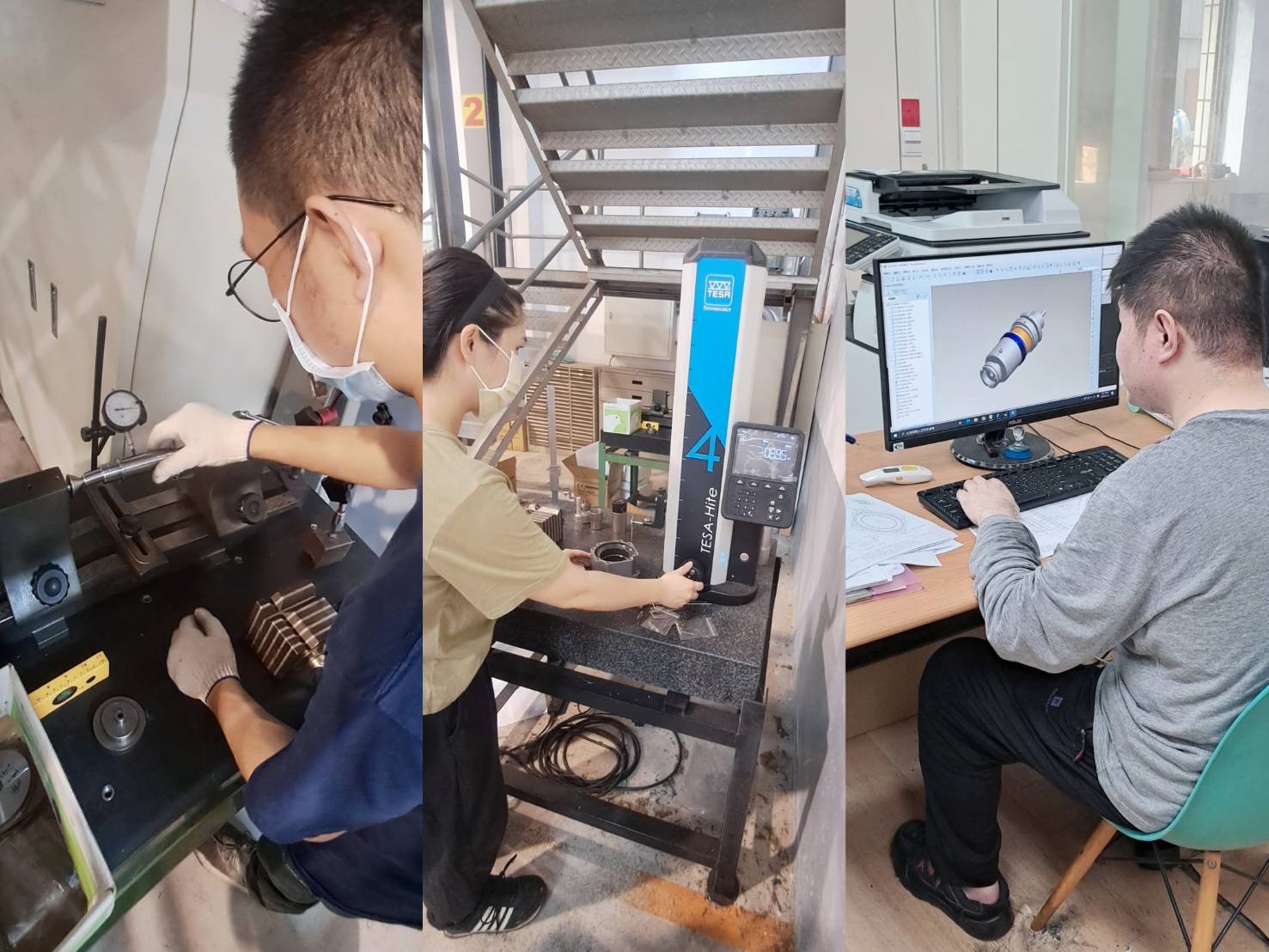

Research and Development & Drawing & Detection:

We specialize in producing high-value engineered parts and assemblies with complex designs and demanding quality requirements. We consistently surpass our customers' expectations in terms of quality, cost, and delivery by combining advanced CNC machining technologies with a robust ERP system, a lean approach, and a team of highly skilled personnel.

If you are interested, please send us the drawings of your CNC parts to the following email address: [email protected].

We will be able to provide you with the best possible price.

↓ Please click to see more

High level of Completion CNC Parts

Drawings → [email protected]

Screw, Nut, and Hardware Manufacturing:

These can all be customized in small quantities. We manufacture screws based on detailed customer specifications, so customers need to provide us with drawings and samples.

Common international standards we adhere to include:

◎We also offer custom production services.

Materials:

Common surface plating treatments: